some of Our Methods:

At Studio Chilap we take a multi-media approach and use the widest toolbox available in order to bring the best results to our customers. We are always on the lookout for new methods, but the following is a few which we use every building day.

Analysis: If only photos are provided, we use software to adjust for lens distortion, estimate dimensions, and make reasonable assumptions when reality is ambiguous.

Metals: CNC, photo-etch, soldering and using adhesives on brass and other metals.

CAD/CAM Design: We are quick on Solidworks®, Autocad® and other design software. We could turn versions of complex designs within days – an important cost and time advantage.

Fine Wood and Brickwork: Coming from a background in carpentry and balsa model aircraft, we are comfortable working with basswood, balsa and MDF and strike the best balance between appearance, accuracy and durability.

For brick walls, we offer a few techniques to choose from, including brick-by-brick laying, molded plaster and 3D printed walls.

Real Glass: Rather than plastic sheet that is commonly found in commercial miniatures, we use real glass because of its superior refractive qualities, transparency and authenticity. The reflections in this photo for example would not be the same if plastic was used.

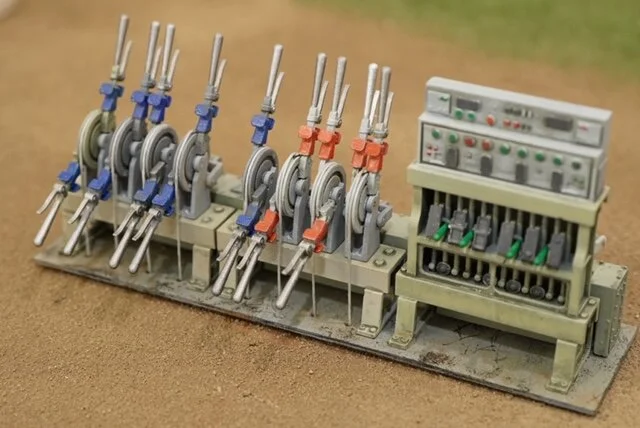

3D Manufacturing: In addition to our in-house 3D resin printers, we also have access to proven independent 3D print shops with the latest industrial equipment to produce the finest prints commercially available. Our experience also allows us to create designs that print well and avoid the common pitfalls associated with SLA or SLS print systems.

Materials Integration: The integration of materials, of methods old and new, is often the most challenging aspect in model construction. What is the best method to hide the layer lines appearing on resin 3D prints? How much does balsa shrink after wetted with enamel paint? Is styrene better than wood in some applications? What tolerances must be taken into account when 3d printing the smallest hole possible? The selection of material and approach has implications not just in quality, but in time used for re-work, and cost. We have made all sorts of mistakes in the past, so the you don’t have to.